Insights

Vibration Control: the vital factor.

part 2.

How vibration can affect R&D facilities.

Read part one of our insight here.

Machinery and scientific instruments can be extremely sensitive to vibration and manufacturers usually impose strict requirements on the environmental conditions in which equipment is to be housed. The result is a room with exceptionally low levels of permitted vibration, far below any threshold of human perception.

Instruments such as optical microscopes, lasers and lithography systems are common, many observing or interacting with materials at nanometre scales and below. The exact requirements for science and research buildings usually depend on the type of science to be undertaken and the intended equipment to be used. As such, it is necessary to develop appropriate criteria and end-user aspirations early in the design phase of the project, with stakeholder and design team engagement being crucial during this period.

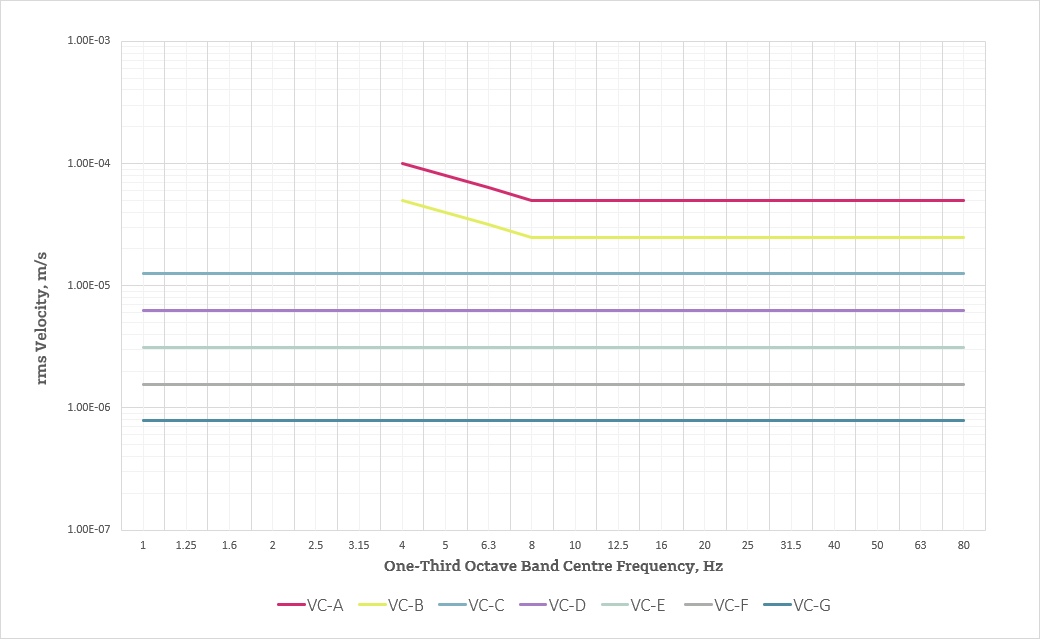

In terms of specification setting, there are no universally accepted criteria for vibration limits within sensitive facilities, though it is common to rely on the Vibration Criterion (VC) curves stated within Institute of Environmental Sciences and Technology (IEST) documentation. The VC criteria were “originally developed for use in the semiconductor industry but have found application in a wide variety of technological applications”

These curves describe spectral velocity limit bands and are used to classify levels of vibration in structures. Manufacturers often adopt VC criteria for acceptability of the environment in which equipment will be housed, though bespoke criteria may also be expected.

It is an important point to note that any vibration specification should include contributions from all sources that may reasonably affect the environment.

This means that vibration from people moving within the building, vibration from building services and operational vibration such as experimental equipment or day to day deliveries must all be accounted for. Each aspect may have distinct characteristics which must be considered in detail.

Vibration assessment methodology:

There is well established Acoustic industry guidance for the measurement and assessment of groundborne noise and vibration. Determining the amount of vibration to which instruments may be exposed in future science and research buildings requires a combination of measurement and predictive study to forecast and control environmental conditions. It should be noted that the groundborne component forms part of the puzzle and a successful design must practicably account for a diverse range of sources, unique to the operation of the building. Another point of note is that many calculation frameworks for predicting vibration in buildings are based on empirical methods, often finding limitations in facilities requiring very low levels of vibration internally.

Vibration measurements:

In-situ measurements are the first step to evaluate the vibration levels at the project location. In many cases, measurements allow an opportunity to appraise the aspirations of the end-users and provide an early steer on the design.

Through measurement surveys, the results may illuminate optimal vibration conditions in specific regions of a site, guiding the positioning of the most sensitive equipment, or identifying areas where enhanced image resolution my occur. Measurements within existing developments, poised for conversion into a laboratory space, may find that aspirational targets cannot be achieved in all regions. In such cases, a conversation can begin on zoning allocations, isolation systems or structural intervention.

Monitoring systems should capture the footprint of the site, specifically the sensitive areas, and may also necessitate measurements below ground if basement areas are to be utilised (which tend to have lower vibration levels).

Ensuring that measurement systems can capture the time history and resultant spectral contributions of vibration is crucial. The sensors used must be capable of measuring very low levels of vibration without spurious self-noise contributions and their installation must be carefully implemented so as to avoid issues which may inhibit the truthful capture of ground motion. Recording the time history in multiple axes is also necessary, as most scientific equipment is sensitive to vibration in multiple orientations.

Vibration predictions:

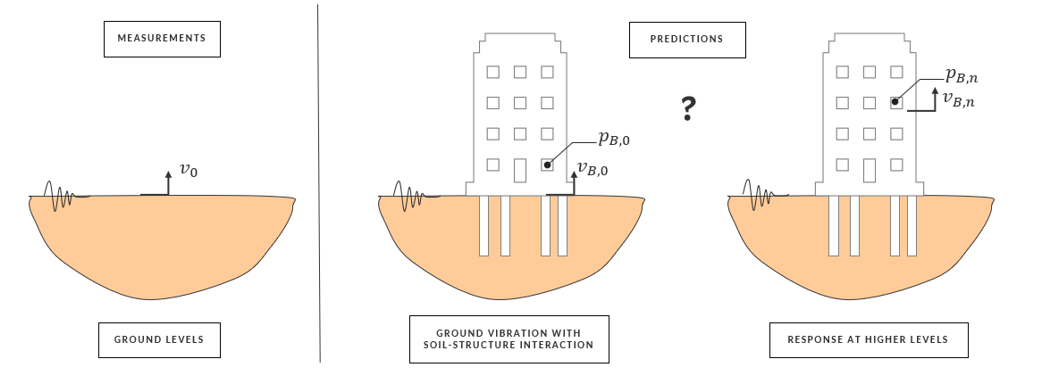

Measurement data captured from the survey is utilised in the prediction of groundborne vibration levels within the proposed structure. Models should be specific to building designs, materials, soil interactions and other pertinent parameters to ensure that sensible design options and prediction scenarios can be provided to the client.

Within the structure, predictions of footfall-generated vibration can be undertaken by structural engineers and/or vibration consultants. Vibration from building services or process equipment can be designed based on knowledge of operating speeds and masses, or in some cases by using data from similar installations. In the latter case, it is important to ensure that the recycling of data considers the difference between existing and proposed supporting structures. Advanced techniques to characterise the vibration sources should ideally be implemented.

In most cases, 3D simulations are often the best means of predicting the dynamic behaviour in complex structures. The Finite Element (FE) technique is common (though other methods exist) since it can accurately replicate the geometry and dynamic nature of structural designs. When considering groundborne vibration, ensuring soil-structure interaction effects, structural loads, and measurement data are combined within a single prediction framework is important. The output of a successful model can then be post-processed and compared to the specified criteria.

Once the structural design is complete, further reduction measures such as zoning of sensitive spaces, walking routes, building services isolation and/or equipment isolation can be implemented. Such measures are often iterations of the original vibration model, though may take on separate work streams in some cases.

Conclusion.

Vibration control in sensitive buildings is an important part of building design in R&D facilities and comes with multiple challenges. The design affects users, spaces, and devices. Getting it right is crucial to delivering a successful science-led facility.

Multiple aspects must be considered, these include the environmental vibration conditions at the proposed location to the structural, proposed layouts, building services strategy and day-to-day internal operations. Detailed measurement and modelling strategies should be allowed for in every sensitive scheme and a collaborative approach should be fostered with end users and the entire design team early in the process to provide the best solution for the client.