Insights

15 ways to reduce waste: TRUE certification.

The why, what, and how of this new assessment method.

During the last decade, there’s been an indisputable influence of environmental rating tools on UK building design. While not all are as comprehensive as we might hope, they have certainly shown how a formalised certification can help change mindsets and provide a framework to achieve sustainably-focused outcomes.

A few weeks back, I discussed the ways we can move towards a circular economy within the built environment, noting that the new London Plan has introduced a requirement for major developments to provide a Circular Economy statement with planning submissions.

While this is just a first step, it’s an important move to ensuring Circular Economy principles are considered during the design process, but also throughout building operation.

For anyone committed to formalising these principles, there’s an emerging assessment method focusing on reducing operational waste for any building – new or existing.

Called TRUE Zero Waste, it launched at the end of 2017 and has already been adopted by US developments, such as the HP headquarters and Tesla factory in California.

T- total

R – resource

U – use (and)

E – efficiency

The TRUE certification method can be used by facilities management teams and building occupiers to define, pursue, and achieve zero waste goals; cut their carbon footprint; and support public health. It is administered by the Green Business Certification Inc. (GBCI) and is US based, although it can be assessed on developments in any country.

It’s a points game

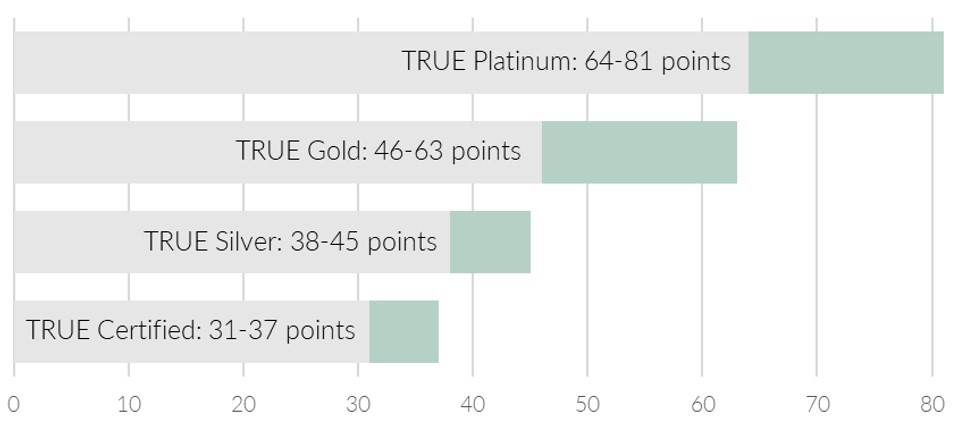

The assessment is like most environmental assessment methods, in that there are a number of certification levels. These can be reached by achieving a certain number of credits, out of a maximum of 81.

The assessment focuses on operational resource use only, rather than waste and resource management during initial building design and construction stages.

The 15 assessment categories cover:

1. Redesign

Focus on appropriately designed waste stores and reviewing the existing supply chain.

2. Reduce

Aim to reduce packaging and resource use and implement monitoring programmes.

3. Reuse

Encourage material reuse, on-site and off-site.

4. Compost

Segregate compostables for processing.

5. Recycle

Monitor and increase waste recycling.

6. Zero waste reporting

Encourage and incentivise the use of environmentally friendly products.

7. Diversion from landfill

Increase diversion of resources from disposal.

8. Zero waste purchasing

Encourage and incentivise the use of environmentally friendly products.

9. Leadership

Encourage behaviour change within the organisation.

10. Training

Educate site users to facilitate responsible waste management.

11. Zero waste analysis

Regularly conduct waste audits.

12. Upstream management

Work with vendors to encourage sustainable practices.

13. Hazardous waste prevention

Effectively manage and document hazardous waste movements.

14. Closed loop

Encourage use of recycled or local products.

15. Innovation

Use of upcycling programmes and other innovative activities.

What you need to know.

There are a couple of preconditions for any project seeing TRUE Certification: the entire facility must be owned by the same developer, or maintained under one operating body, and the building must have a baseline of waste diversion data. For existing projects, this could be up to 12 months’ worth of data, but for completely new facilities as little as one month’s data could be used.

You can then pick and choose credits to pursue based on the individual project, depending on what level of certification is being targeted.

The TRUE Zero Waste certification process:

Want to know more?

As sustainability consultants with experience in operational waste strategies, we can provide advice and support to anyone wishing to pursue TRUE certification.

For more information about TRUE or any other zero waste initiatives, contact Katherine Adair.