Insights

The truth behind timber: part 2.

A sustainable solution.

As we explored in part 1 of this insight series, the climate emergency we’re facing has brought to light the importance of a faster adoption of engineered timber in construction.

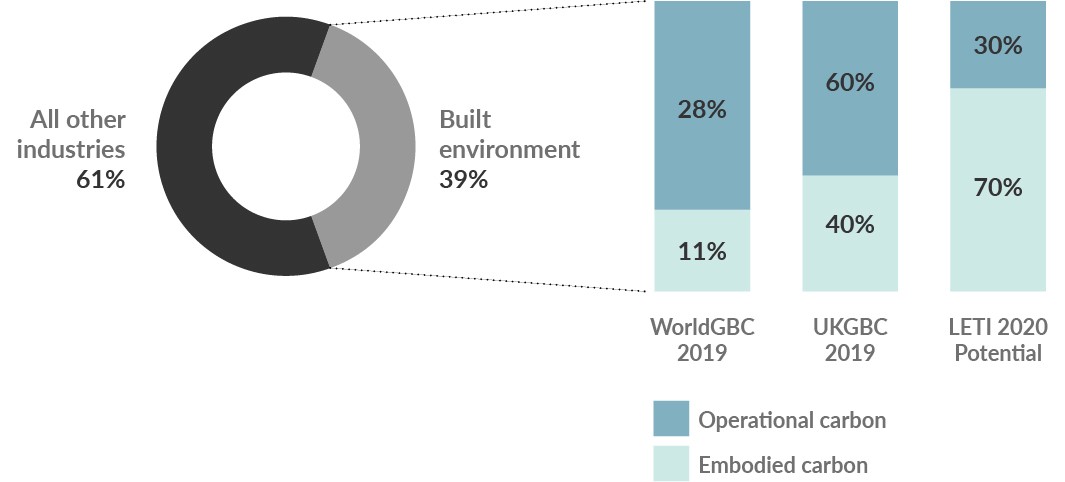

Carbon emissions in buildings stem from two elements: operational and embodied carbon. There is already a lot of attention on reducing emissions from an operational perspective, thanks to the move to all-electric energy strategies. This means that as the grid decarbonises, the proportion of emissions from operation will diminish and the embodied emissions will take precedent.

There needs to be a huge drive to cut down on embodied carbon. The best place to start is within the structure of a building as this represents ~50% of the total emissions and lasts for the lifespan of the building.

Structures are currently typically comprised of steel and concrete or a hybrid of the two. The production processes of these materials rely on the extraction of finite materials and are very energy intensive, which leads to high embodied emissions. In fact, if cement (the primary constituent of concrete) was a country, it would be the third largest carbon dioxide emitter in the world.

By comparison, timber is classified as a renewable material, and the carbon emissions released during the processing and production are low. It’s also important to note that timber is a far greater natural insulator than its competitors due to air pockets within its cellular structure. This can lead to reductions in operational associated emissions or at least reduce the amount of insulation required within a building.

When looking at lifecycle emissions, cross-laminated timber (CLT) has the lowest of all conventional materials.

Sequestered carbon.

In addition to the lower emissions associated with its production, perhaps the most significant benefit of timber is its ability to store carbon. As wood grows, it takes CO2 from the atmosphere where it reacts to form cellulose and a series of other complex organic compounds called Lignin, which lock up the carbon.

Approximately half of the dry mass of wood is carbon – carbon that would otherwise be carbon dioxide, contributing to the greenhouse effect and ultimately climate change.

This carbon locked away within the wood is known as the sequestered carbon, and this is often used to offset carbon emissions associated with a development, particularly important as we strive towards a net zero carbon future.

Taking this sequestered carbon into consideration, timber buildings become a key to delivering net zero carbon buildings: in a fully timber structure (with the carbon sequestered accounted for) the reduction in upfront carbon compared to a conventional building (steel and concrete) could be as much as 60%.

Even better is if the wood is to be re-used or recycled, as the carbon stays stored within the wood, retaining its negative contribution to the atmosphere. When constructing with timber, it is easy to design with circular economy principles such as disassembly, as the structures are often comprised of prefabricated units. This allows for high value waste streams to be created, as opposed to wet trades like concrete (which often needs to be smashed out during its end-of-life).

Fundamentally, promoting the use of timber and driving a demand for it encourages the growth of more forest to maintain the supply – thanks to FSC, PEFC and equivalent certifications – and therefore more carbon capture.

It’s clear timber will have a key role to play in sustainable construction and, ultimately, the creation of climate-conscious buildings of the future.

Look out for part 3, coming soon, where we explore the fire safety requirements for timber construction.